Table of Contents

ToggleHeat stress isn’t just about discomfort; it is a major operational risk. According to OSHA’s heat illness prevention guidelines, high temperatures can significantly increase the likelihood of workplace accidents. When temperatures on a job site climb past 90°F, concentration drops, accident rates rise, and productivity slows to a crawl. For safety managers and procurement teams, the question isn’t whether you need cooling gear—it’s about which type actually works for an 8-hour shift.

If you are looking for a cooling safety vest, you have likely encountered a confusing mix of options: vests you soak in water, vests filled with ice, and vests that use battery-powered fans. Which one is the “best”? The answer depends entirely on your specific environment and the humidity levels your team faces.

In this guide, we will break down the three main cooling technologies, compare their performance in industrial settings, and explain why modern fan-assisted gear is becoming the standard for safety-conscious companies.

The Three Main Types of Cooling Vests

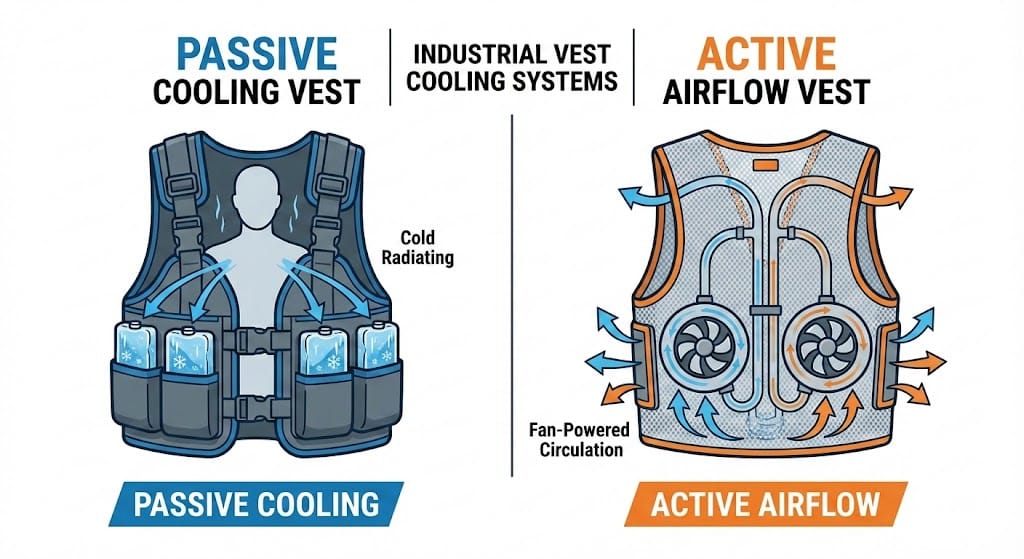

Before you commit your budget to a specific solution, it is critical to understand the mechanics behind how these vests regulate body temperature.

Evaporative Cooling Vests (The Water Soak Method)

These are the most traditional and affordable options on the market. They use specialized fabrics (like PVA or polymer crystals) that absorb water.

How they work: You submerge the vest in water for a few minutes, wring it out, and wear it. As the water evaporates from the fabric, it draws heat away from the wearer’s body.

The Pros:

Low upfront cost.

Lightweight when dry.

No batteries or electronics required.

The Cons:

Humidity Failure: This is the biggest drawback. Evaporation requires dry air. If you are working in high humidity (common in many construction zones), evaporation stops, and the vest essentially becomes a heavy, warm wet towel.

Dampness: They can leave the wearer’s underlying shirt wet, which can cause chafing or skin irritation over a long shift.

Ice Pack / Phase Change Cooling Vests

These vests feature internal pockets designed to hold frozen gel packs or Phase Change Material (PCM) inserts.

How they work: This is conductive cooling. The frozen packs sit directly against the torso, absorbing heat.

The Pros:

Immediate, intense relief.

Works in any environment, regardless of humidity or airflow.

The Cons:

Weight: A fully loaded ice vest can add 4 to 6 pounds (approx. 2-3 kg) to a worker’s load. For a construction worker cooling vest, this extra weight can accelerate fatigue.

Logistics: The cooling effect typically lasts only 2 to 3 hours. Once the ice melts, it becomes dead weight. To make this work for a full shift, you need on-site freezers and a rotation schedule for the packs.

Fan Cooling Vests (Circulating Air)

A vest with fan technology represents a shift toward active cooling rather than passive cooling. This is the category seeing the most rapid adoption in modern industrial sectors.

How they work: Two small, powerful fans are integrated into the lower back of the vest. They pull fresh air in and circulate it between the fabric and the skin. This airflow rapidly evaporates sweat, using the body’s natural cooling mechanism but supercharging it.

The Pros:

High Humidity Performance: Because the fans force air movement, they continue to aid evaporation even when the air is stagnant.

All-Day Duration: With high-capacity lithium batteries, a cooling fan jacket or vest can run for 10-12 hours—covering an entire shift on a single charge.

Stay Dry: The airflow keeps the worker’s skin dry, preventing heat rash.

Why a Cooling Safety Vest Must Be High-Vis

In industrial environments, cooling cannot come at the expense of visibility. This is a common pain point: a worker puts on a cooling vest, but then has to wear their mandatory safety vest over it.

This layering creates two problems:

It traps heat, negating the cooling effect.

It restricts movement.

A dedicated cooling hi vis vest solves this by integrating the cooling technology directly into an ANSI/ISEA compliant garment.

When you choose a solution that combines high-visibility materials (like fluorescent yellow or orange mesh) with active cooling fans, you ensure compliance with site safety regulations without forcing workers to wear double layers. This “all-in-one” approach is safer and more comfortable.

Furthermore, reflectivity matters. A cooling reflective vest needs to maintain its brightness after months of use. Soaking-style vests often degrade their reflective tape faster because of the constant cycle of wetting and drying. Fan-based vests, which stay dry, typically preserve the integrity of the reflective glass beads for longer.

Selecting the Right Construction Worker Cooling Vest

Construction sites are uniquely harsh environments. The gear used here needs to be tougher than what a weekend gardener might use. When sourcing a construction worker cooling vest, you need to look at three factors: durability, battery safety, and ease of use.

Durability and Material

The fabric needs to resist tears and snags. Polyester blends are standard, but the weave should be tight enough to hold the air pressure generated by the fans (to ensure circulation) while being breathable enough to not feel like a plastic bag.

Battery Safety

Since a cooling safety vest with fan relies on a lithium-ion battery, safety is paramount. High-quality manufacturers use batteries with over-charge and short-circuit protection. The battery pocket should be positioned so it doesn’t dig into the worker’s ribs when they bend or lift.

The “PPE” Factor

Procurement teams often look for a ppe cooling safety vest that fits seamlessly into existing uniform protocols. Does the vest have a clear ID badge holder? Are the pockets accessible? Can the fans be removed easily so the vest can be washed? These practical details determine whether the crew will actually wear the gear.

Comparison: Fan Cooling vs. Ice vs. Evaporative

To help you visualize the trade-offs, here is a quick comparison based on typical industrial use cases.

| Feature | Evaporative Vests | Ice Pack Vests | Fan Cooling Vests |

| Cooling Method | Water Evaporation | Frozen Inserts | Forced Air Circulation |

| Duration | 1-4 Hours (depends on humidity) | 2-3 Hours | 8-12+ Hours (Battery dependent) |

| Weight | Light (when dry), Heavy (when wet) | Heavy (4-6 lbs) | Light (Fans + Battery < 1 lb) |

| Humidity Performance | Poor | Excellent | Good |

| Worker Dryness | Wet/Damp | Risk of Condensation | Dry |

| Maintenance | Soak & Dry | Requires Freezer | Charge Battery |

As the table suggests, if your goal is long-duration cooling without the logistic headache of on-site freezers, the cooling fan jacket or vest is the clear winner for logistics and construction.

Maintaining Your Cooling Gear

Investing in cooling gear is an operational expense, so longevity matters.

For cooling fan vests, maintenance is surprisingly simple. The electrical components (fans and cables) are designed to be detachable. Once removed, the vest itself—usually made of polyester—can be machine washed just like a standard safety vest.

This is a significant advantage over some complex ice-vests where the pockets can tear, or evaporative vests that can develop odors if not dried properly. By keeping the cooling system (the fans) separate from the garment, you can replace just the worn-out fabric part while keeping the expensive electronics, reducing long-term replacement costs.

Making the Right Choice for Your Team

Heat stress is preventable. While basic hydration and breaks are essential, equipping your team with the right technology can drastically improve their daily experience and efficiency.

While ice and evaporation have their place, the industrial trend is moving toward the vest with fan. It offers the balance of light weight, long battery life, and high visibility that modern sites demand.

At Yolite, we understand the specific needs of site safety. We don’t just resell generic gear; we manufacture reflective materials and clothing designed to meet rigorous standards. When you source directly from the manufacturer, you ensure that the reflective quality meets code and the cooling technology is integrated perfectly into the garment.

If you are ready to upgrade your team’s safety and comfort, it is time to look at professional-grade solutions.

Frequently Asked Questions

Most standard batteries for these hi vis safety cooling vests last between 8 to 12 hours on a low-to-medium setting, sufficient for a full work shift.

Yes, but you must remove the fans, battery, and cables first. The vest fabric is typically machine washable once the electronics are detached.

Yes, our specific models are designed with ANSI-compliant background materials and reflective tape to ensure Class 2 or Class 3 compliance.

Yes. Unlike evaporative vests, a cooling fan jacket forces air circulation, which helps evaporate sweat and cool the body even in humid conditions.

Yes, as a manufacturer, we specialize in fulfilling bulk orders for procurement teams and safety distributors.

Don’t let heat stress become a liability on your job site. Instead of juggling ice packs or settling for wet, heavy gear, equip your workforce with a cooling safety vest designed for the reality of industrial work. As a direct manufacturer, Yolite integrates high-performance fan systems directly into ANSI/ISEA compliant garments, ensuring your team stays cool without compromising on visibility.

Reach out to our team today to discuss your project specs or request a sample of our vest with fan technology.