Reflective HTV (Heat Transfer Vinyl) has become one of the most popular materials for custom apparel, sportswear, and safety products. You may have seen it on running shirts, backpacks, pet harnesses, or even children’s school bags that shine brightly when hit by car headlights.

This blog explains what reflective HTV is, how it works, and how you can use it to create eye-catching and safer designs—whether you’re a DIY crafter or a business producing custom gear.

Table of Contents

ToggleWhat Is Reflective HTV?

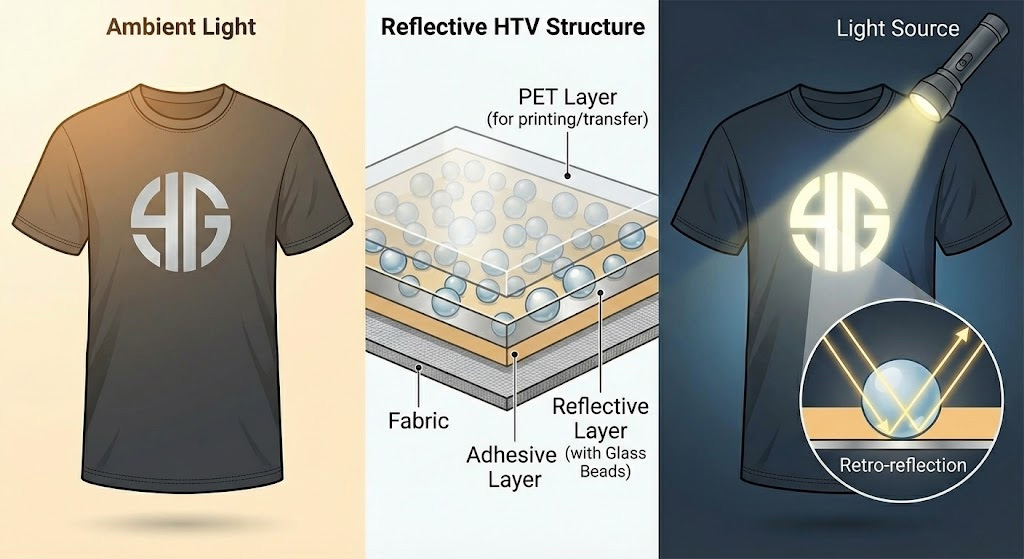

Reflective HTV is a special type of heat-transfer vinyl that contains millions of tiny glass beads. These beads return light back toward its source, making the material appear extremely bright in low-light or nighttime conditions.

The vinyl is cut into shapes or logos, then applied to fabric using a heat press. Once transferred, the reflective film becomes part of the garment and remains highly durable and washable.

How Reflective HTV Works

The core of Reflective HTV is the micro glass bead technology.

Each bead acts like a tiny mirror:

Light hits the bead’s surface

Light bends and reflects internally

The bead sends light directly back to its source

This phenomenon is called retroreflection, the same technology used in traffic signs and safety vests.

Because of this, reflective HTV greatly improves visibility for:

Runners and cyclists

Kids walking to school

Workers near traffic

Nighttime dog walking

Common Uses of Reflective HTV

Reflective HTV is widely used across lifestyle, safety, and personalization industries:

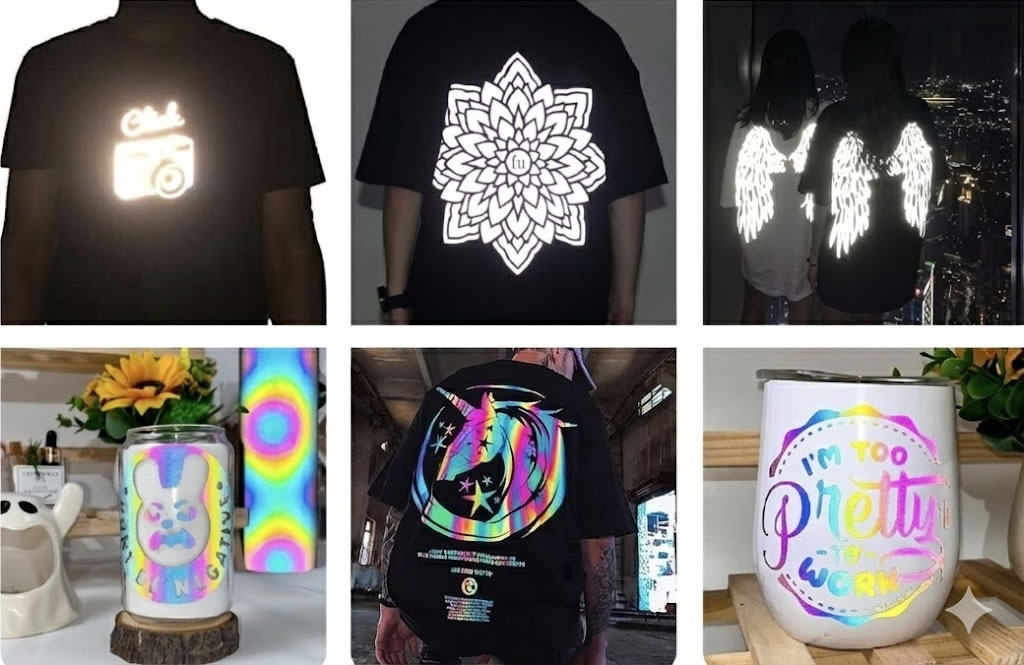

Sports & Running Gear

Logos, stripes, and decorative elements increase nighttime visibility.

Workwear and Safety Apparel

Enhances visibility for construction, roadwork, and warehouse workers.

Pet Accessories

Reflective names or patterns on collars, harnesses, and vests.

DIY Craft Projects

Custom designs on hoodies, backpacks, tote bags, and costumes.

Children’s Products

School bags, jackets, and accessories with reflective patches for safer travel.

Types of Reflective HTV

Reflective HTV comes in several variations depending on your needs:

| Type | Description | Best Use |

|---|---|---|

| Standard Gray Reflective | Most common, high brightness | Running gear, workwear |

| Color Reflective (Blue, Red, Rainbow, etc.) | Fashion + visibility | Lifestyle clothing, bags |

| PU Reflective HTV | Soft PU material with reflective surface, thin and smooth finish | T-shirts, fashion apparel |

| Stretch Reflective HTV | Flexible for stretch fabrics | Yoga wear, sportswear |

| Pattern Reflective (Hexagon, Camouflage, etc.) | Decorative + reflective | Urban fashion, streetwear |

| Sublimation-Block Reflective | Prevents dye migration | Polyester fabrics |

How to Apply Reflective HTV (Step-by-Step)

Using reflective HTV is easy for both beginners and professionals:

Cut the vinyl using a plotter (mirror the design).

Weed the excess material.

Position the vinyl on the garment.

Use a heat press (typically 140–160°C for 10–15 seconds).

Peel off the PET carrier film.

Let the garment cool before washing.

For businesses, a standard heat-press workflow ensures consistent quality and durability.

Reflective HTV vs. Regular HTV: What’s the Difference?

| Feature | Reflective HTV | Regular HTV |

|---|---|---|

| Visibility at Night | ★★★★★ | ★★☆☆☆ |

| Safety Function | Yes | No |

| Brightness | Extremely bright | Non-reflective |

| Appearance | Metallic/gray or colored | Matte, flock, glitter, etc. |

| Cost | Slightly higher | Lower |

If nighttime visibility is important, reflective HTV is the better choice.

How Long Does Reflective HTV Last?

High-quality reflective HTV is designed to be:

Wash-resistant

Crack-resistant

Suitable for daily wear

Long-lasting even under outdoor conditions

For industrial buyers, durability depends on glass bead density, adhesive quality, and washing method.

Customization Options (For Brands & Businesses)

If you are a brand, wholesaler, or safety gear company, reflective HTV can be customized in many ways:

Custom shapes, logos, letters

Custom reflectivity level (e.g., ≥ 330 cd/lx/m²)

Custom colors or patterns

Flame-retardant reflective material

Stretch or soft-touch formulas

Roll width & length customization

Bulk OEM/ODM production

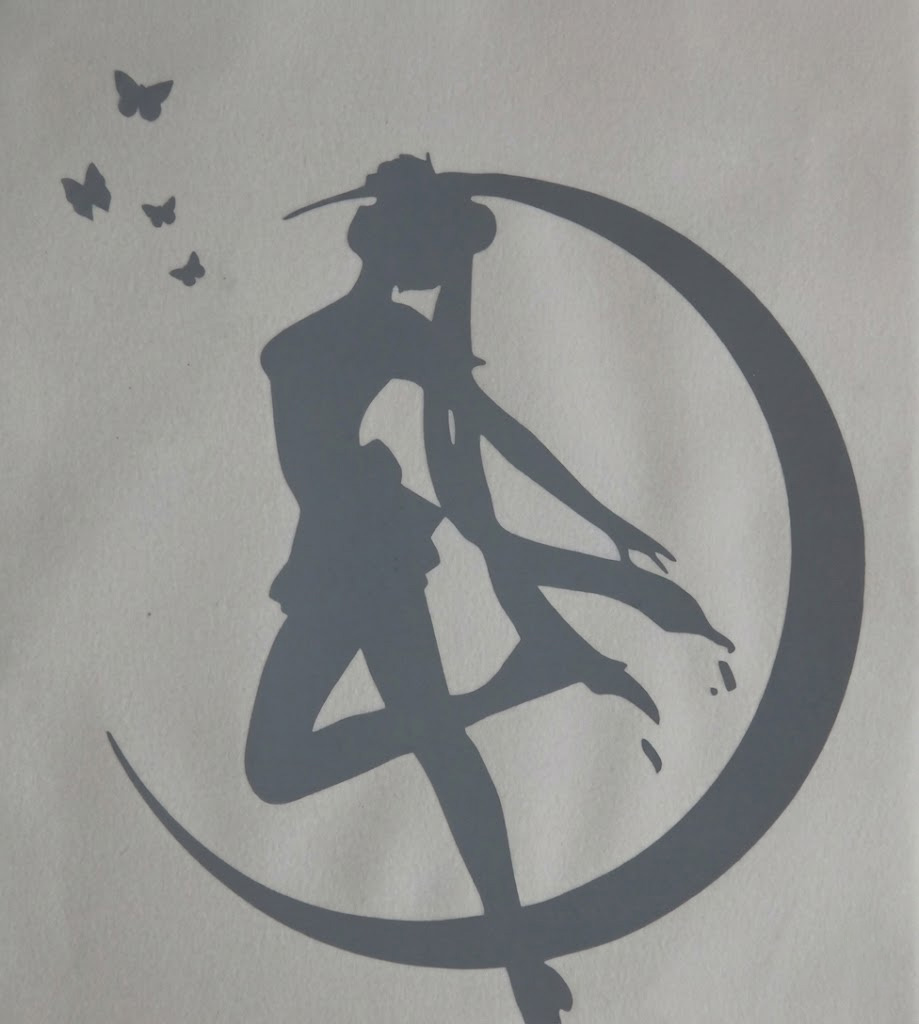

How to Make a Reflective HTV Logo

Cut and Weed the Logo

Create your logo in vector format and mirror the design before cutting.

Use a cutting plotter to cut the reflective HTV, then carefully weed away the excess material, leaving only the logo on the carrier sheet.

Position the Logo

Place the weeded reflective HTV logo onto the garment with the carrier film facing up.

Make sure the logo is properly aligned before heat pressing.

Heat Press the Logo

Use a heat press at the recommended settings.

Press at 140–160°C (285–320°F) for 10–15 seconds, then peel off the carrier film warm or cool.

Reflective HTV Heat Settings (Temperature, Pressure & Application Tips)

Reflective HTV requires more precise heat settings than standard heat transfer vinyl because of its glass-bead or micro-prismatic reflective layer. Using incorrect temperature or pressure can result in poor adhesion or reduced reflectivity.

Recommended heat press settings for reflective HTV:

Temperature: 300–320°F (150–160°C)

Time: 10–15 seconds

Pressure: Medium to firm, even pressure

Mirror cut: Yes

Peel: Warm or cold peel (always check manufacturer guidance)

When pressing reflective HTV, avoid excessive heat. Too much temperature or press time may flatten the reflective surface and reduce brightness. Always ensure the garment is flat and pre-pressed for 2–3 seconds to remove moisture and wrinkles before application.

Pro Tip:

If you are working with layered designs, apply reflective HTV as the top layer only, since it does not layer well under other vinyl types.

| Setting | Recommended Value |

|---|---|

| Temperature | 300–320°F (150–160°C) |

| Press Time | 10–15 seconds |

| Pressure | Medium to firm |

| Pre-Press | 2–3 seconds |

| Peel Method | Warm or cold peel |

| Layering | Top layer only |

| Mirror Cut | Yes |

Reflective HTV Time and Temp: Getting the Perfect Bond Without Overheating

One of the most common questions crafters ask is how long and how hot reflective HTV should be pressed. Unlike regular HTV, reflective vinyl is more sensitive to overheating.

Standard time and temperature guidelines:

Heat press: 10–15 seconds at 300–320°F

Home iron: High heat (cotton setting), firm pressure, press in sections for 15–20 seconds

Second press: Optional, 5–8 seconds with a Teflon sheet

Pressing reflective HTV for too long can cause the adhesive to weaken or the reflective particles to dull. If the vinyl does not fully adhere after the first press, increase pressure slightly rather than increasing temperature.

Always perform a stretch test after peeling. If the edges lift, cover with a Teflon sheet and repress for a few seconds.

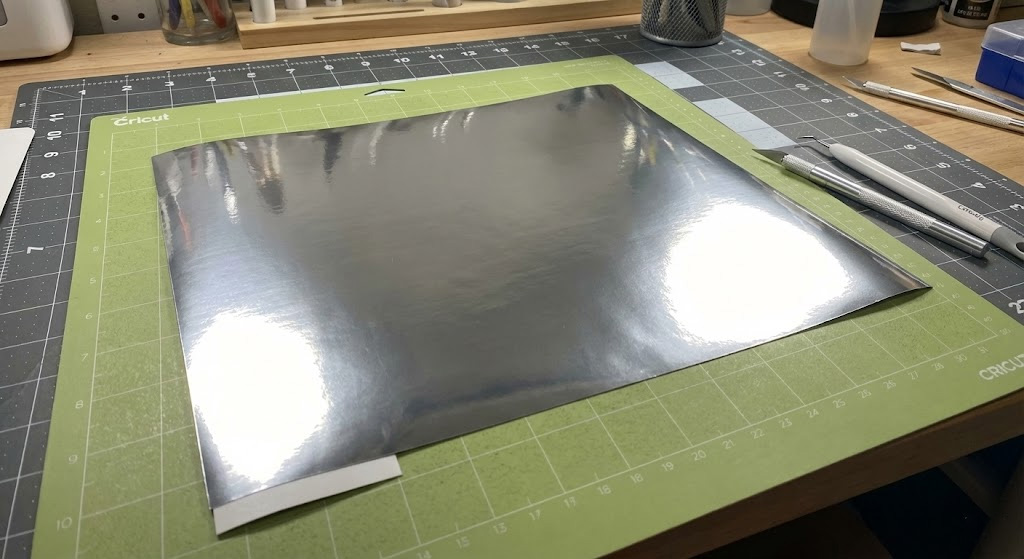

Reflective HTV Cut Settings for Cricut, Silhouette & Other Cutting Machines

Because reflective HTV is thicker than standard vinyl, correct cut settings are essential for clean designs and easy weeding.

General cutting recommendations:

Blade: Fine-point blade

Material setting: Start with “Reflective HTV” if available, or “Iron-On+”

Pressure: Medium to high (test before full cut)

Cut side: Shiny side down

Mirror image: Always ON

For detailed or small designs, reduce cutting speed and perform a small test cut first. If the vinyl does not weed cleanly, slightly increase pressure rather than running multiple passes.

Reflective HTV is less flexible than regular HTV, so simpler shapes and bold designs usually produce the best results.

| Setting | Recommendation |

|---|---|

| Cutting Machine | Cricut / Silhouette |

| Blade Type | Fine-point blade |

| Material Setting | Reflective HTV / Iron-On+ |

| Cut Side | Shiny side down |

| Mirror Image | ON |

| Pressure | Medium–High |

| Test Cut | Always recommended |

Reflective HTV is a simple but powerful way to improve visibility and create stunning designs. Whether you’re customizing a running shirt, adding safety elements to workwear, or designing stylish reflective graphics, reflective HTV offers both functionality and creativity.

If you’re a business looking for OEM/ODM reflective solutions, professional factories (like YoLite) can supply high-quality reflective materials with stable performance and customization options.

FAQs About Reflective HTV

Yes. Good-quality reflective HTV is highly durable and safe for machine washing.

Yes—just make sure to use the right temperature and consider sublimation-block HTV to avoid dye migration.

Yes, but choose stretch reflective HTV for best results.

Reflective HTV is widely used on children's jackets and backpacks for safety.