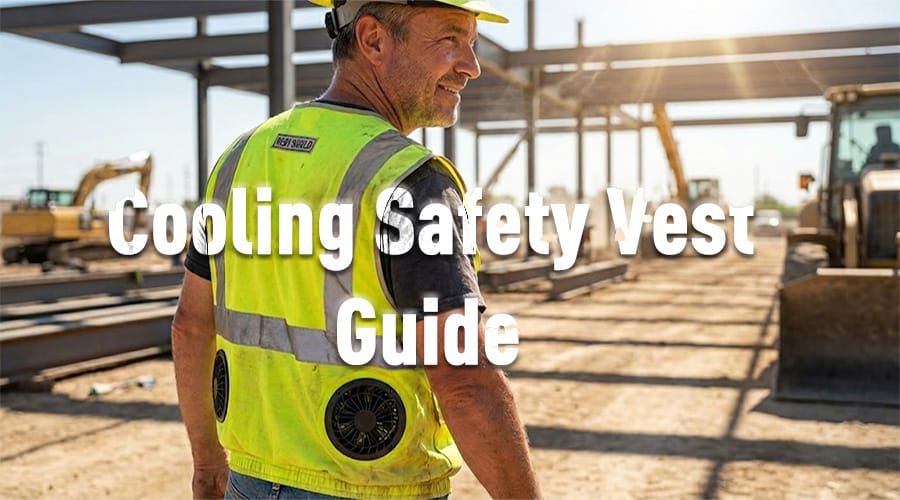

Have you ever driven past a construction site and noticed workers in bright neon vests, practically glowing under the sun? That vivid orange, yellow, or green isn’t just a bold fashion choice—it’s a critical safety feature. This article explores why construction workers wear neon, delving into the science, regulations, and practical benefits of hi vis safety vests. You’ll discover how these garments protect workers, enhance visibility, and comply with industry standards, with insights for procurement teams and safety managers sourcing reliable gear. Let’s uncover why neon is non-negotiable on the job site.

The Science of Neon: Why Visibility Matters

Construction sites are chaotic—cranes swing, machinery hums, and workers move fast. In this high-risk environment, being seen can mean the difference between safety and disaster. Hi vis safety vests are crafted with two essential materials: fluorescent fabric and reflective tape. The fluorescent fabric, typically in colors like fluorescent yellow or orange, contains special dyes that absorb ultraviolet light from the sun and re-emit it as visible light. This makes the vest appear brighter and more noticeable during the day, enhancing safety in daylight conditions. Conversely, the reflective tape, while less effective in daylight, plays a vital role at night. When illuminated by light sources such as headlights, it reflects strongly, making workers instantly visible from hundreds of feet away.

This dual-material design is critical for preventing accidents. For instance, a worker in a high visibility vest might be spotted by a forklift operator in time to avoid a collision. Studies indicate that high-visibility clothing reduces accident rates by up to 20% in industries like construction. For procurement teams, selecting vests with high-quality fluorescent fabric and durable reflective tape ensures workers remain safe across all shifts.

Regulations Driving Neon Use in Construction

Why do construction workers wear neon? Regulations are a major driver. Standards like ANSI/ISEA 107 in the U.S. and EN ISO 20471 in Europe mandate high-visibility clothing for workers in hazardous environments. These standards require hi vis safety vests to incorporate both fluorescent fabric for daytime visibility and reflective tape for nighttime visibility, ensuring workers are seen in all conditions. Compliance is a legal necessity in construction, safeguarding lives and avoiding penalties.

For example, ANSI/ISEA 107 categorizes high-visibility gear into three classes based on risk. Class 2 vests, common in construction, mandate a minimum amount of fluorescent fabric and reflective tape for moderate-risk tasks. Class 3 provides greater coverage for high-risk areas like highways. Procurement managers sourcing safety vests with features like pockets should ensure they meet these standards for safety and compliance.

Practical Benefits of Neon Vests for Workers

Beyond regulations, neon vests provide practical benefits that make them essential. A hi vis safety vest enhances visibility while offering functionality. Vests with pockets allow workers to carry tools, radios, or IDs without extra gear, streamlining tasks and keeping essentials accessible on fast-paced sites. The fluorescent fabric ensures daytime visibility, while the reflective tape provides crucial nighttime protection, delivering round-the-clock safety.

Neon vests also improve team coordination. A hi vis vest with a logo can identify workers by company or role, minimizing confusion on multi-contractor projects. On a site with dozens of workers, logos enable supervisors to quickly locate their team. For buyers, customizable vests reinforce branding while prioritizing safety.

Comparison Table: Types of Hi Vis Vests

| Feature | Class 2 Vest | Class 3 Vest | Safety Vest with Pockets |

|---|---|---|---|

| Visibility Level | Moderate (day/night) | High (low-light, high-risk) | Moderate to high |

| Reflective Tape | 201 sq. in. minimum | 310 sq. in. minimum | Varies, often Class 2 |

| Best Use | General construction | Highway work, heavy machinery | Tool-heavy tasks |

| Customization | Logos, colors | Logos, full coverage | Pockets, logos |

| Cost Range | $10–$20 | $20–$40 | $15–$30 |

Why Wear Safety Vests? Addressing Common Questions

Why wear safety vests when regular clothing might suffice? The answer lies in their superior visibility and durability. Unlike regular clothing, neon vests feature fluorescent fabric that maintains daytime visibility and reflective tape that ensures nighttime reflectivity, even after enduring dirt, sweat, and repeated washing. They’re lightweight, keeping workers comfortable during long shifts. For safety managers, investing in durable, high-visibility gear cuts replacement costs and maintains consistent protection.

Neon vests also serve as a signal. They instantly mark someone as a worker, not a bystander, reducing unauthorized access to hazardous areas. For procurement teams, choosing vests with features like tear-resistant fabric or adjustable fits further enhances worker safety and comfort.

Choosing the Right Hi Vis Gear for Your Team

Choosing the right high visibility vest requires balancing safety, functionality, and cost. For construction, Class 2 or Class 3 vests are recommended, depending on site risks. Features like pockets or logos add value without sacrificing compliance. A safety vest with pockets, for instance, may cost more but eliminates the need for separate tool belts, boosting productivity. Ensure the vest includes high-quality fluorescent fabric for daytime visibility and durable reflective tape for nighttime safety, meeting relevant standards.

Consider material durability and breathability, especially in hot climates. Reflective tape quality is critical—subpar tape fades, reducing visibility. Partnering with a trusted manufacturer like Yolite ensures compliant, durable vests tailored to your needs.

Frequently Asked Questions

Hi vis safety vests ensure visibility in low-light or busy conditions, reducing accident risks. The fluorescent fabric and reflective tape meet standards like ANSI/ISEA 107. Contact us for compliant options.

It should feature durable fluorescent fabric, high-quality reflective tape, and ample pocket space for tools or IDs. Breathability enhances comfort. Request a sample to test our designs.

Yes, logos identify workers by company or role, reducing confusion on multi-team sites while reinforcing branding. Inquire about customization options.

Reflective safety vests use fluorescent fabric and reflective tape for enhanced visibility, unlike regular vests, and are built for durability and compliance.

Construction sites feature heavy machinery and low-visibility zones, making neon vests with fluorescent fabric and reflective tape vital for safety. Contact us for bulk orders.

Ready to equip your team with reliable hi vis safety vests? As the original manufacturer, Yolite offers durable, compliant gear tailored to construction needs. Whether you need safety vests with pockets, custom logos, or bulk orders, we’ve got you covered. Send us an inquiry today to discuss your requirements or request samples—let’s keep your workers safe and visible.