Choosing the right retail packaging for reflective vests isn’t just about looks — it’s about balancing cost, presentation, and practicality. Whether you’re supplying safety clothing for retail shelves or preparing products for shipment, packaging can influence how buyers perceive your brand.

This guide explains five common packaging types used for reflective safety garments. Each has unique advantages, materials, and cost implications, helping you decide which fits your order size, market, and price point.

Table of Contents

ToggleColor Box Packaging

Color box packaging remains one of the most popular options for reflective products. Made from coated or white card paper, it’s printed in full color and often laminated for a smooth finish. The result? A vibrant box that instantly communicates professionalism and brand identity.

Color boxes are perfect for retail shelves because they combine protection and strong visual appeal. They often include a hanging hole or window to display the product inside. While printing setup costs make this option better suited for medium to large orders, it provides a polished retail experience that buyers appreciate.

Header Bag Packaging

Header bag packaging (also called hanging poly bags) combines simplicity and cost efficiency. It uses a transparent plastic bag sealed with a printed paper header card, which usually features the logo, barcode, and basic product info.

The design is lightweight, easy to display, and works well for smaller, lighter reflective items like armbands, belts, or compact vests. It’s also convenient for manual packing during small-batch production. For brands aiming to stay budget-friendly without sacrificing shelf visibility, header bags are a smart option.

Laminated Plastic Bag Packaging

Laminated plastic bags (also called composite bags) are known for their glossy printed surface and strong sealing. These bags are made from PET/PE or OPP/CPP laminated films — giving them a sturdy texture and vibrant printing quality.

However, for small quantity orders, full-surface printing may not be cost-effective because it requires setup fees and minimum order quantities (MOQs). In such cases, many buyers prefer transparent laminated bags with an inner printed insert card. This hybrid approach reduces printing costs while keeping the professional look of full packaging.

For large volume production, fully printed laminated bags are ideal, offering moisture protection and high-impact branding at scale.

Printed PET Folding Box

A printed PET folding box is made from transparent PET material, offering both clarity and rigidity. The product remains visible through the packaging, while printed graphics or UV logos add premium appeal.

This type of packaging highlights the actual product while maintaining a clean, professional finish. It’s durable, recyclable, and perfect for products positioned in the mid to high-end market. PET boxes usually feature a tuck-end closure and may include a hanging tab for display.

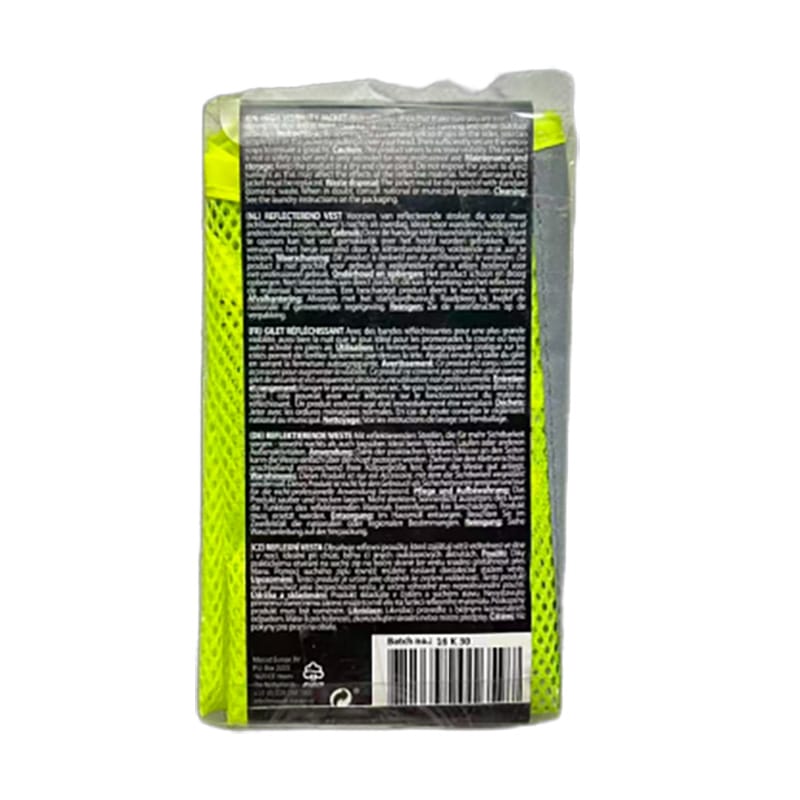

PET Folding Box with Printed Insert Card

This is a creative blend of structure and design — a clear PET box combined with a printed color insert card inside. The insert card provides branding, usage information, or multilingual instructions, while the PET shell offers transparency and durability.

Compared with full-printed PET boxes, this option offers the same professional appearance but at a slightly lower cost, especially when packaging needs frequent content updates. It’s ideal for reflective vests that require both clarity and brand storytelling.

Quick Comparison Table

| Packaging Type | Material | Visual Appeal | Cost Range | MOQ Suitability | Typical Use |

|---|---|---|---|---|---|

| Color Box | Paperboard | Excellent | Medium–High | Medium–Large | Retail shelves |

| Header Bag | Poly + Card | Good | Low | Small–Medium | Lightweight items |

| Laminated Bag | PET/PE | High | Variable | Medium–Large | Moisture protection |

| Printed PET Box | PET Plastic | Excellent | Medium–High | Medium–Large | Premium display |

| PET Box + Insert | PET + Paper | High | Medium | Small–Medium | Balanced presentation |

Packaging Advice and Next Steps

Your packaging doesn’t just protect the product — it represents your brand’s quality and values. Selecting the right type means balancing appearance, practicality, and budget efficiency.

Frequently Asked Questions

Typically, the MOQ is around 5,000–10,000 pcs due to printing setup costs. For smaller runs, we suggest transparent laminated bags with insert cards to reduce expenses.

Yes, we can print your logo using UV, screen printing, or offset methods depending on your design requirements.

Laminated bags with insert cards or header bags are the most budget-friendly options for smaller batches.

Yes, sample packaging can be arranged upon request. Contact us for more details and cost estimates.

If you’re planning your next reflective product shipment and want a packaging solution that fits your quantity and market, contact us directly. As the original reflective vest manufacturer, we can help customize packaging to your exact needs — saving both time and cost by sourcing straight from the source.